We are well aware of how important the reliability of the light source is to a LED light's stability. And what makes our LED light outstanding from competitors is the key component--- the K-COB chip.

What is K-COB?

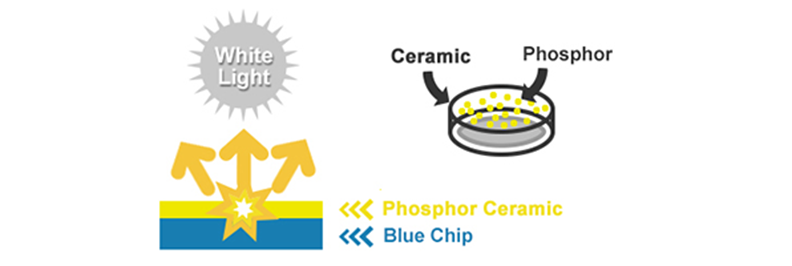

K-COB is a unique LED packaging pattern- by replacing the regular organic material such as epoxy/silicone which commonly used in white LEDs with self-developed phosphor ceramic (or ceramic phosphor converter) !

VS

It's the phosphor ceramic for LED application;

Phosphor ceramic has much lower thermal resistance comparing to the molding of epoxy and silicone;

Hard surface, impact proof and good resistance for temperature&humidity change.

Production

Why Choose K-COB?

Comparison

| Thermal degradation | Either silicone or epoxy are not able to dissipate the heat fast enough. It's resulted in phosphor degradation&failed. |

| Discoloration at High temp | Discoloration happened after long-time endurance of high temp. |

| Corrosion | Corrosion happened when moisture&PH changing occurs. |

| Superior reliability | Patented “dual channel heatsinking”.The heat disspate from PCB&ceramic cover via sapphire; |

| Higher light density | Light density of KCOB could be 30% higher than regular COB. |

| Lumen intensity | Ceramic never age and degradation. All KCOB series is LM-80 certificated. |

*Patented “dual channel heatsinking”.