Nowadays, due to the awareness of energy-saving and ECO lifestyles, more and more traditional light source such as MHL, HPS has been replaced with LEDs. LED is a mature technology and has been through a long time since invented, however, there are still some types of lighting applications that LED hard to do well such as stadium Lighting, high mast application, and fishing light. This kind of case always requiring of : high reliability, high ground lux level, and glare prevention.

Technical requirements for high mast application

WHAT IS PHOSPHOR CERAMIC?

Comparison of different phosphorous material

Here are the comparison data of main phosphorous materials in the market:90% of supplier are using phosphorous powder with silicone cake. The phosphorous film is made by NittoSiO2, phosphorous glass made by Nichia, and phosphorous ceramic (laser ceramic) made by K-COB.

| Item | Silicone cake | Film | Glass | Ceramic |

| Heat conductivity@25℃ | 0.18W/m.K | 0.18W/m.K | 1.46W/m.K | 13.37W/m.K |

| Quantum efficiency | 92% | 92% | 92% | 97% |

| Thermal quenching@80% | 175℃ | 175℃ | 175℃ | 210℃ |

| Weather resistance | Bad resistance to wet & heat high heat expansion | Bad resistance to wet & heat high heat expansion | Good resistance to wet & heat Low heat expansion | Good resistance to wet & heat Low heat expansion |

| Corrosion resistance | No corrosion resistance | No corrosion resistance | Dissolve to HF&H3PO3 | Dissolve to H3PO3 |

| Uniformity | Bad | Good | Good | Best |

| Lifespan | Aged easily | Aged easily | Base material stable, phosphorous getting aged easily | High intensity |

WHAT IS K-COB?

K-COB Dual Heat Sinking Channel

| Name | Traditional silicone COB | K-COB |

| Simple diagram | ||

| Explanation | The heat-generating by the wafer could be radiating from the PCB only, and as the heat has not been conducted would remain inside of silicone cake, it would reduce the LED efficiency&shorten its lifespan. | The heat could be radiating from both PCB directly and laser ceramic surface by sapphire. This dual heatsinking structure allows us to make COB at smaller size but with higher wattage and better reliability. |

The combination of excellent heatsinking performance from phorsphor ceramic and dual-channel heat-leading structure,K-COB resolve the COB heatsinking problem once and for all.

We separate two main heat source of LED chip and phosphor by dual heatsink channel design. This design help to reduce chip junction temperature effectively.

Thermal Resistance data comparison

The actual testing data is tested by equipment MicReD® T3Ster, as you can see, K-COB thermal resistance is just 72% of traditional COB.

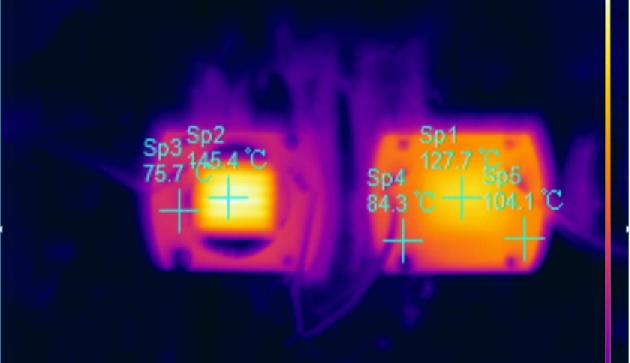

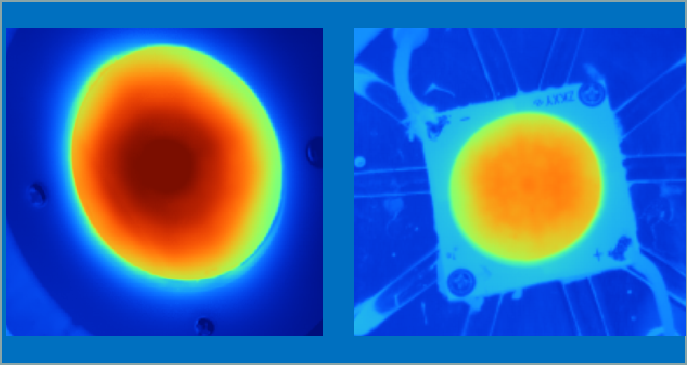

Comparison of COB & KCOB (infrared image)

Uniformity of surface temperature

The right one is normal COB, and other is KCOB, they are under the same testing condition. From the pics above, we can tell the KCOB sample has much better heat-sink performance.

Comparison of COB & KCOB

Lumen intensity data

(The data from original LM-80 report, K-COB is the one and only COB supplier who get LM80 certificated for single 600w chip )

KCOB ceramic characteristic curve

KCOB (lamp) product actual test

K-COB light source family Our main wattage is 100w,300w,600w,1000w ,1200w and 1600w ....

We hope that this guide will be helpful to know what is K-cob and phosphor ceramic. If you want to connect with our lighting experts, kindly feel free to place a call at +86-0591-620978629 or drop an email at daniel.lin@zkxyled.com.

Post time: Dec-24-2021