Heads-Up Display (HUD) technology shows information directly in the user‘s view. HUDs are important in cars and aircraft because they provide useful data without distracting the user. Phosphor materials are essential in display systems as they help convert light into different colors. Ceramic materials enhance performance by making the displays more durable and efficient. K-COB is a special LED packaging method. It replaces common organic materials like epoxy and silicone used in white LEDs with a self-developed phosphor ceramic. This innovation improves the quality and lifespan of LEDs. By using ceramic phosphor converters, K-COB offers better light performance and stability. These advancements make HUD systems more reliable and effective. Overall, the combination of HUD technology, phosphor materials, and ceramic enhancements leads to superior display solutions.

Background

General Properties of Phosphors and Relevance to Display Technologies

Phosphors are materials that emit light when they receive energy. They are important in display technologies because they turn energy into visible light. This light is needed to create clear and bright images on screens. Phosphors help make colors look better and displays brighter. Without phosphors, display systems would not show accurate and appealing visuals.

Phosphors are used in many display devices. These include televisions, computer monitors, and Heads-Up Displays (HUDs). They improve how these systems work by providing steady and reliable light. Phosphors can emit different colors, which is essential for full-color displays. As display technologies get better, the need for high-quality phosphors increases.

Types of Phosphors

There are different types of phosphors used in display technologies. Two common types are rare-earth phosphors and alkaline-earth phosphors.

Rare-earth phosphors contain rare-earth elements like europium, terbium, and yttrium. These elements have excellent light-emitting properties. Rare-earth phosphors can produce bright and stable colors. This makes them ideal for high-performance displays. They are often used where color accuracy and brightness are very important.

Alkaline-earth phosphors are made from elements like calcium, strontium, and barium. These phosphors are valued for their efficiency and lower cost. Alkaline-earth phosphors can produce a wide range of colors. They are commonly used in everyday display devices. These phosphors offer a good balance between performance and affordability, making them suitable for mass-market products.

Each type of phosphor has its own benefits. The choice of phosphor depends on what the display system needs. Factors like color range, brightness, and cost influence which phosphor to use. Knowing the different phosphors helps in designing better display technologies.

Introduction to Ceramic Materials and Their Characteristics

Ceramic materials are hard, inorganic, and non-metallic solids made from powdered chemicals. They are known for their durability and stability. In display technologies, ceramics are used to improve the performance and lifespan of components.

One important feature of ceramic materials is their high thermal conductivity. This means ceramics can effectively spread out heat. This helps prevent overheating in electronic devices. High thermal conductivity is crucial for keeping display systems working well, especially in high-power applications like HUDs.

Ceramics also have excellent mechanical stability. They resist wear and tear, making them suitable for environments where durability matters. Additionally, ceramic materials are chemically stable. They do not easily react with other substances. This stability ensures that display components stay functional for a long time.

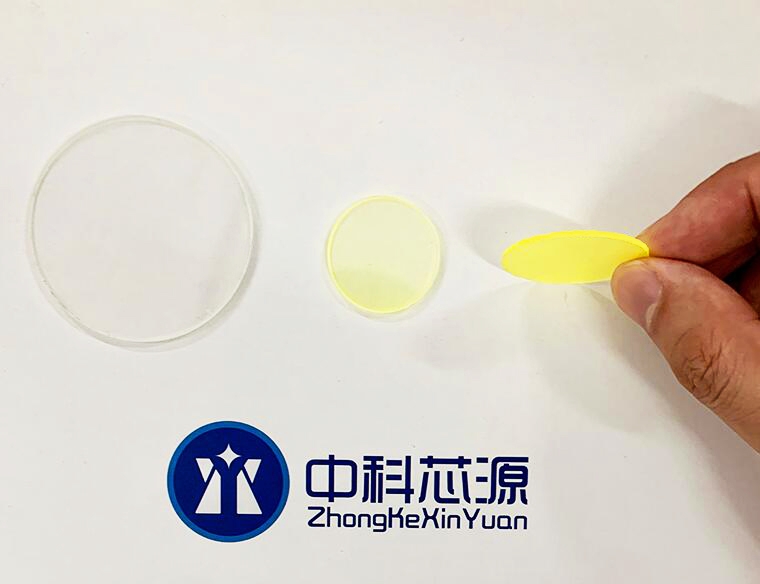

Our self-invented phosphor ceramic is an inorganic material with high thermal conductivity and lighting efficiency. It is better than traditional mixtures of epoxy or silicone with phosphor. We have five international invention patents and many other patents and certifications. We are the only supplier with LM80 certification for high-power COB. This unique phosphor ceramic improves the performance and reliability of HUD systems.

Phosphor Ceramic Materials

Composition and Synthesis of Phosphor Ceramics

Phosphor ceramics are made by mixing phosphor materials with ceramic bases. The process starts by choosing the right phosphors that will emit the needed colors. These phosphors are then mixed with ceramic powders like alumina or silica. The mixture is carefully controlled to ensure the phosphors are spread evenly in the ceramic.

Our phosphor ceramic is made using a special method that ensures high thermal conductivity and lighting efficiency. This method makes the material better than traditional epoxy or silicone-based phosphor converters. The advanced process allows for better performance and a longer life for the phosphor ceramics used in HUD systems.

Types of Phosphor Ceramic Materials Used in Advanced HUDs

Advanced HUDs use different types of phosphor ceramic materials to achieve the best performance. These materials are chosen based on how they emit light, their ability to handle heat, and their strength.

One type of phosphor ceramic used in HUDs is based on rare-earth elements. These ceramics provide high brightness and excellent color accuracy. They are perfect for applications where clear and vibrant displays are needed. Another type is alkaline-earth-based phosphor ceramics. These offer good efficiency and are cost-effective. They are suitable for mass-produced HUD systems where a balance between performance and cost is important

Additionally, our self-invented phosphor ceramic has unique formulations that improve both thermal conductivity and lighting efficiency. This innovation allows HUD systems to work more efficiently and last longer. The special makeup of our phosphor ceramics ensures they meet the high standards of advanced HUD applications.

Key Properties

Phosphor ceramics used in HUD systems have several important properties that make them suitable for high-performance displays.

- Superior Reliability: Our phosphor ceramics are very reliable. They keep working well over time, ensuring that HUD displays stay clear and accurate.

- Patented “Dual Channel Heatsinking”: This special feature allows heat to be spread out from both the PCB and the ceramic cover using sapphire. Effective heat spreading prevents overheating and makes the HUD system last longer.

- Higher Light Density: The light density of K-COB is up to 30% higher than regular COB. This means our phosphor ceramics can produce brighter and more vivid displays, improving the user experience.

- Lumen Intensity: Ceramic materials do not age or degrade over time. This ensures that the light output stays strong and consistent throughout the life of the HUD system.

- LM-80 Certification: All K-COB series phosphor ceramics have LM-80 certification. This certification confirms the long-term performance and reliability of our materials, ensuring their quality and effectiveness in advanced HUD applications.

These properties make our phosphor ceramics an excellent choice for improving the performance and durability of HUD systems.

Advantages of Phosphor Ceramics for HUDs

Enhanced Brightness and Color Accuracy

Phosphor ceramics make HUD displays much brighter. Higher brightness makes the information easier to see, especially in bright places like daylight. Additionally, phosphor ceramics offer better color accuracy. This means the colors shown are more true to life, providing a better visual experience for users.

High Thermal and Mechanical Stability

HUD systems produce heat when they operate. Phosphor ceramics have high thermal stability, allowing them to manage and spread out heat effectively. This stops the display from getting too hot, which can cause damage and reduce performance. Moreover, phosphor ceramics are mechanically stable. They can handle physical stresses and stay intact for a long time, ensuring the HUD system remains reliable.

Long Lifespan and Resistance to Environmental Degradation

Phosphor ceramics are tough and last a long time. They resist damage caused by environmental factors like humidity, temperature changes, and exposure to light. This resistance ensures that HUD systems keep working well over time without losing much performance. Users can depend on displays made with phosphor ceramics to last longer.

Energy Efficiency Improvements

Phosphor ceramics help HUD systems use energy more efficiently. They need less power to produce the same level of brightness compared to traditional materials. This efficiency leads to lower energy use, which is good for the environment and reduces operating costs. Improved energy efficiency also allows for longer battery life in portable HUD applications.

Applications in Advanced HUD Systems

Use in Automotive HUDs

Automotive HUDs show important information like speed, navigation directions, and safety alerts directly in the driver’s view. Phosphor ceramics improve these HUDs by providing clear and bright displays that are easy to read. This enhances driver safety by allowing them to see critical information without looking away from the road. The durability and reliability of phosphor ceramics ensure that automotive HUDs work well in different driving conditions.

Military and Aerospace HUD Applications

In military and aerospace settings, HUDs are used in pilot displays and targeting systems. These applications need high precision and reliability. Phosphor ceramics provide the necessary brightness and color accuracy for clear visibility in tough environments. The high thermal and mechanical stability of phosphor ceramics ensures that HUDs can handle the demanding conditions of military and aerospace operations. This reliability is crucial for mission-critical tasks where performance cannot fail.

Integration into Wearable HUDs

Wearable HUDs, like augmented reality headsets, benefit greatly from phosphor ceramics. These devices need lightweight and efficient display components to be comfortable and effective. Phosphor ceramics offer high light density and energy efficiency, making them ideal for portable and wearable HUDs. The long lifespan and resistance to degradation ensure that wearable HUDs stay functional and provide a consistent user experience over time. This integration improves the usability and functionality of augmented reality devices.

Final Words

K-COB phosphor ceramic materials make HUD systems better. They create brighter and clearer displays. These materials last longer and use less energy. K-COB works well in cars, military equipment, and wearable devices. They are reliable and improve the performance of advanced HUDs. By choosing K-COB phosphor ceramics, you get high-quality and efficient display solutions.

Contact us today to enhance your HUD technology!

Post time: Jan-28-2025