In the past two years, with the continuous development and change of LED market and technology, COB has become a competitive place for all LED packaging enterprises.According to relevant data, the overall share of COB in China's packaging products has exceeded 7%, which is widely used in cob led street light, stadium light, sport lights and other high-brightness application equipment of high-power LED, its demand will increase from 18.5 billion in 2014 to 27 billion in 2017, the compound annual growth rate will reach 13%.

Recently,K-COB company has released the world's leading level of watts to kilowatts cob technology.

The previous LED light source with phosphor powder and silica gel materials will encounter technical bottlenecks when the power exceeds 100W, and the LED application market is therefore limited in the field of general lighting. Through material innovation, we can achieve 1000W, which will drive LED lighting into the high-power application market such as industry, ports and airports.

Material innovation breakthrough when fluorescent ceramic meets LED

Material innovation is to transform the LED light source through transparent fluorescent ceramic materials, make breakthroughs from the source of materials, coupled with special technology and structure, and then develop 1000W high wattage LED light source. This is a revolutionary breakthrough of our technology led, from ceramic material sintering equipment, highly confidential formula, to unique packaging technology, KCOB has realized the whole chain technology, and has completely independent intellectual property rights, patent layout in the international.

Under the condition of high power, transparent fluorescent ceramic materials also have higher stability and reliability. It has the characteristics of high thermal conductivity, high temperature resistance, corrosion resistance, and good thermal impact resistance. "In optics in physics, the requirement is high power and beam angle; In terms of heat dissipation, the greater the area, the better the heat dissipation, these two things are actually contradictory, it is very difficult to do them well at the same time. And our light source can be a good solution to this problem, the reason lies in the particularity of our material, combined with the unique packaging structure, can do even a small area, can also be very good heat dissipation.

It is reported that the average electricity saving rate of high-power outdoor lights is about 70%, and the carbon emissions will be significantly reduced. There will be a large potential market in the future, with high economic and social benefits

K-cob leads the new market for kilowatt-level lighting

It can be said that it is the double breakthrough of material and structure that has created this big breakthrough of LED light source industry. From 100W to 1000W, a few decades ago, even a few years ago, many people could not imagine the technological breakthrough, but today, KCOB have made it.

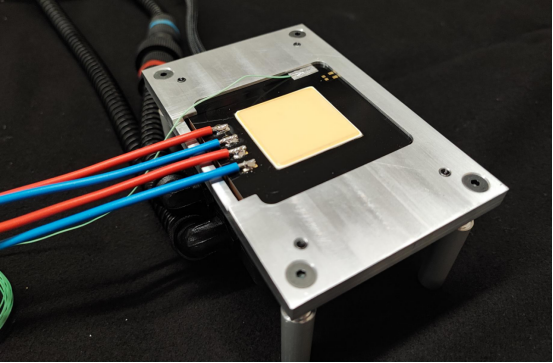

The most remarkable feature of transparent fluorescent ceramic materials is that they can be packaged with high power density. To achieve this, a unique package thermal conductivity structure must be developed. KCOB has become the first high power led factory in the world to produce 1000W light source module, which makes LED enter the high-power lighting market and realize the full replacement of traditional lighting.

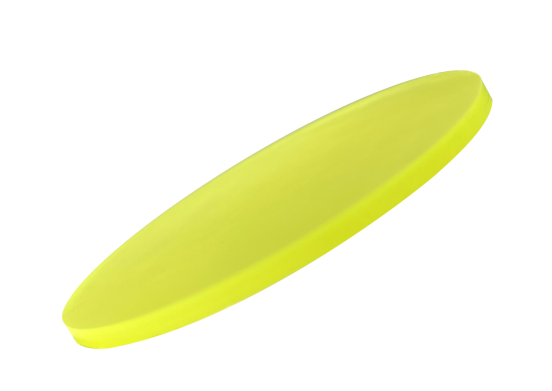

At present, the 600W light source module produced by KCOB has been applied to the lighting of the training venues of Beijing 2018 Winter Olympics,replacing the 2000W metal halide lamp. And this kind of high-power ceramic chip, 1000W chip is only a little bigger than 1 yuan coin, and the past 150WLED light source is as big as the ceiling lamp in the conventional home.

Post time: Aug-11-2022