1. Introduction

Since the invention of blue LEDs, people have begun to develop various high-power white LED packaging technologies, hoping that white LEDs can replace traditional lighting sources. At present, the production technology of white LEDs on the market is mainly divided into two mainstreams. The first is to use phosphors to convert the blue light or ultraviolet light generated by blue LED or ultraviolet LED into two-wavelength or three-wavelength white light, respectively. This technology is called fluorescence. The second type is a multi-chip white LED, which combines two (or more) LEDs of different colors to form white light. The first method can obtain white light with medium and high color temperature, but has poor color rendering for warm color temperature. In order to solve this problem, red phosphors are usually added, but the excitation efficiency of red phosphors is low, resulting in a low overall light efficiency.

The second method needs to supply power to three chips respectively, the drive circuit is complicated, and the aging attenuation of the three chips is inconsistent, and long-term operation will lead to color temperature shift.

2. Packages of color temperature tunable LEDs

The packaging technology of LED actually draws on the traditional microelectronic packaging technology, but LED has its own uniqueness, and it cannot be done completely according to the microelectronic packaging. The entire LED packaging process mainly includes the selection of packaging raw materials, the design of packaging structure, the control of packaging process, and the optical design and heat dissipation design. The key technology of LED packaging.

Figure 1 Key technologies of LED packaging Traditional multi-chip integrated packaging mostly fixes LED chips on circuit boards according to certain rules, such as aluminum-based copper clad laminates, ceramic circuit boards, etc. While widely used, they also have inherent disadvantages. They are usually composed of a circuit layer (copper foil layer), a thermally conductive insulating layer and a metal base layer, but the thermal conductivity of the thermally conductive insulating layer is extremely low, which becomes the thermal conductivity bottleneck of the circuit board, resulting in the overall thermal conductivity of the circuit board. Only 1.5W/ around mK. Ceramic circuit boards have good thermal conductivity, but have disadvantages such as high cost, unsuitable processing, and high brittleness, and they account for a high proportion of the overall cost of LED devices, and their applications are also limited. In order to solve the above problems, an LED packaging structure has been developed. A window is opened at the die-bonding position of the aluminum-based copper clad laminate, and a pad is placed at the position where the bonding wire is required. Under the copper plate, the LED chip is placed on the area passing through the window, which can greatly improve the heat dissipation performance of the LED.

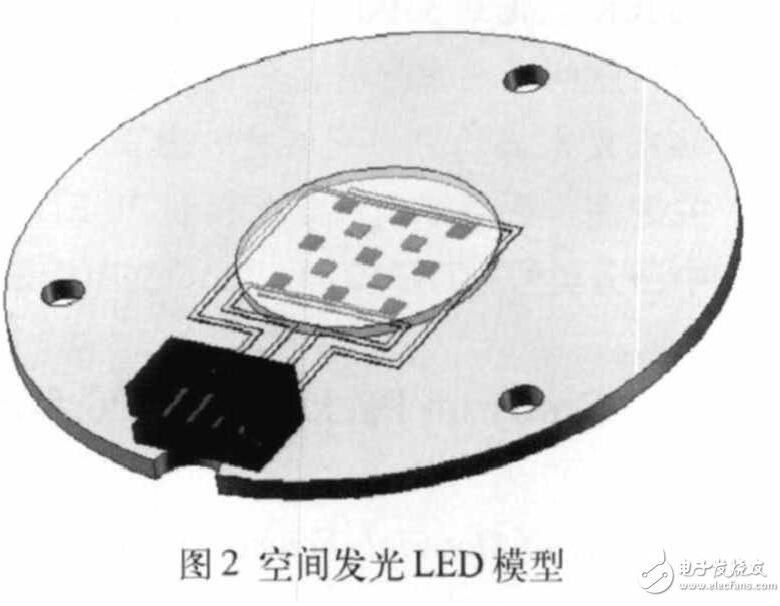

The structural design of the LED is the basis for whether the packaged product can meet the requirements of use. The LED designed in this paper mainly includes:

Package substrate, blue LED chip, red LED chip and yellow-green phosphor, the package substrate is composed of aluminum-based copper clad laminate and aluminum plate, as shown in Figure 2.

Good packaging technology is the key to determining device performance, reliability and life. The method adopted in this paper is as follows: the package substrate adopts aluminum-based copper clad laminate and aluminum plate with high thermal conductivity, the chip is bonded to the aluminum plate, the LED chip adopts a power-type W-class positive chip, and the chip and the package substrate are bonded with high thermal conductivity silver glue (The thermal conductivity is greater than 25W/mK), and the overall packaging is completed by wire bonding, phosphor coating, curing and other processes.

3. Performance test of color temperature tunable LED

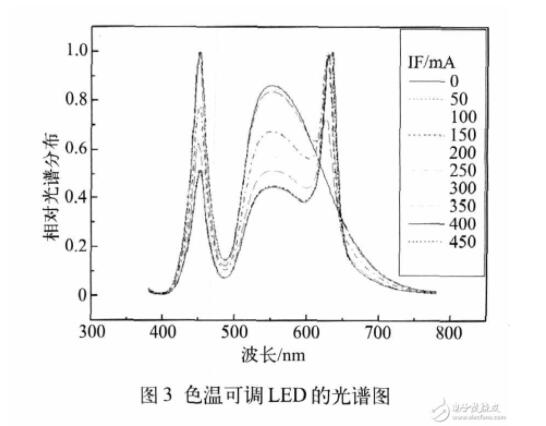

Figure 3 shows the spectrum of the color temperature tunable LED measured by the remote HASS-2000 high-precision fast spectroradiometer. It can be seen from the figure that with the change of the red LED current (from 0 to 450mA), the relative The spectrum will also change accordingly. The spectrum of LED has three peaks at 450nm, 550nm and 628nm respectively. The luminous efficiency of warm color temperature is greater than 68lm/W, and the luminous efficiency of cool color temperature reaches 87lm/W.

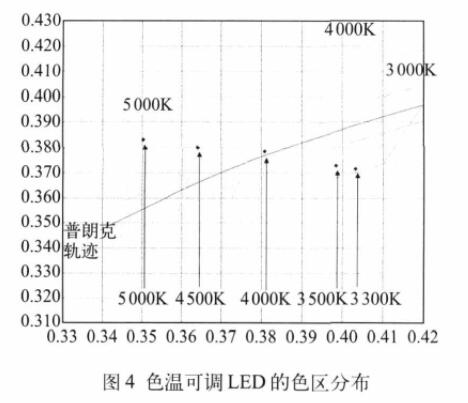

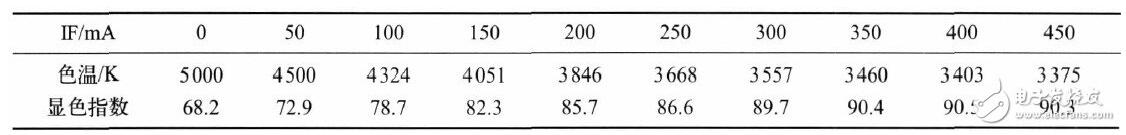

Figure 4 lists the change of the color area distribution of the color temperature tunable LED with the current of the red LED, and Table 1 lists the optical performance parameters of the color temperature tunable LED with the change of the red LED current. It can be seen that the red LED does not In the case of adding current, the color temperature of the LED is 5 000K. In the cool color temperature BIN area, with the gradual increase of the red LED current, the color temperature of the LED module will show a continuous change, from cold light 5 000K to warm light 3 375K, At the same time, the color rendering index of LED will gradually increase, up to 90 or more, which can fully meet the requirements of lighting places for color rendering index.

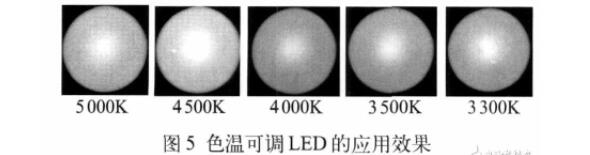

The integrated packaged LED, due to its large operating current, generates a large amount of heat during operation. If the heat accumulated in the pn junction is not conducted out in time, the temperature of the device will rise, and the temperature will have an important impact on the performance of the LED, such as color temperature. change, wavelength redshift, forward voltage drop, etc. Figure 5 shows the application effect of the color temperature adjustable LED. The packaged color temperature adjustable LED module is installed on a 100mm downlight, and the red LED adds different currents to obtain the luminous effect of the downlight. After the downlight was continuously lit for 30 minutes, the temperature of the radiator on the test downlight was 38°C, and the temperature of the aluminum-based copper clad plate was 38.5°C (room temperature 25.2°C), indicating that the color temperature adjustable LED has good heat dissipation performance.

4. Conclusion

This paper introduces a new type of LED with tunable color temperature. A high-power LED chip combined with a metal substrate is used to encapsulate an LED sample of warm white light with tunable color temperature and high color rendering index. The spectral performance, color temperature, and color rendering index of the LED are tested. The current changes, the results show that the LED color temperature can be continuously changed from 3300K to 5000K, the color rendering index can reach more than 90, and it has excellent heat dissipation performance, which can fully meet the requirements of lighting places for color temperature and color rendering index, and has a wide range of applications. prospect.

Post time: Jan-21-2022