Lighting technology has come a long way, with advancements like COB (Chip on Board) and traditional LED (Light Emitting Diode) playing pivotal roles in modern lighting solutions. As more projects demand high-quality and efficient lighting, understanding the differences between COB vs LED technologies becomes crucial. This blog explores the intricacies of both technologies, their comparative advantages, and the unique features of K-COB technology, guiding purchasing departments and wholesale buyers in making informed decisions.

Understanding COB vs LED Technologies

COB (Chip on Board) Technology

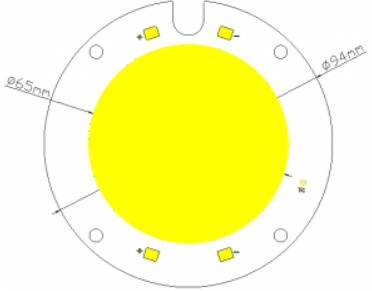

COB technology revolutionizes the way LEDs are used by integrating multiple LED chips on a single substrate. This design creates a single, powerful light source that enhances both light output and efficiency. Unlike traditional LEDs that require multiple diodes to achieve high brightness, COB LEDs streamline this process into a compact, cohesive unit. This configuration is particularly beneficial for applications requiring high brightness and uniform light distribution, such as sports lighting, searchlights, and TV & film lighting.

One of the key advantages of COB vs LED is their ability to deliver a higher lumen output with a more uniform light spread. This is because the multiple LED chips work together as a single module, eliminating the inconsistencies often seen with traditional LEDs. As a result, COB vs LED are increasingly becoming the preferred choice for projects that demand consistent and high-quality illumination.

Moreover, COB technology simplifies the design and installation process. By integrating multiple chips on a single substrate, the need for complex assemblies is reduced, making COB LEDs more efficient and easier to work with. This not only saves time during installation but also reduces the overall cost of the lighting system.

Traditional LED Technology

Traditional LED technology involves separate diodes mounted on individual packages. Each diode operates independently, which can be advantageous for certain applications but often requires more components to achieve the desired light output. These systems frequently need complex assemblies and additional accessories like lenses or reflectors to enhance light distribution.

Despite these challenges, traditional LEDs have their own set of benefits. They are versatile and can be used in a wide range of applications, from general and ambient lighting to decorative purposes. The modular nature of traditional LEDs allows for flexibility in design and customization, making them suitable for projects where specific lighting configurations are needed.

However, achieving uniform light distribution with traditional LEDs can be challenging. Since each diode emits light independently, multiple units are often required to create an even light spread. This not only increases the complexity of the lighting system but can also affect its efficiency and cost-effectiveness.

Comparative Advantages of COB and Traditional LEDs

Light Quality and Distribution

COB LEDs are renowned for their superior light quality and distribution. The integration of multiple LED chips on a single substrate allows for a higher lumen output and a more uniform light spread. This is particularly crucial for applications like sports lighting, where consistent and bright illumination is essential for optimal performance and safety. Searchlights and TV & film lighting also benefit from COB technology, as it ensures a consistent and high-quality light source.

Traditional LEDs, on the other hand, may have varying light outputs depending on the number and arrangement of diodes. Achieving uniform light distribution often requires multiple units and additional accessories, which can complicate the design and installation process. While traditional LEDs are suitable for general and ambient lighting, they may not be the best choice for high-intensity applications that require consistent and high-quality illumination.

Thermal Management

Effective thermal management is critical for maintaining the performance and longevity of LED systems. COB LEDs excel in this aspect due to their integrated design and the use of advanced materials like Copper PCB and phosphor ceramic. These materials enhance heat dissipation, ensuring stable performance even under high-power conditions. The superior thermal management of COB LEDs makes them ideal for high-power applications where maintaining efficiency and reliability is paramount.

Traditional LEDs often require additional components like heat sinks to manage heat, which can increase the complexity and cost of the lighting system. Poor thermal management can lead to reduced efficiency and shorter lifespan, making traditional LEDs less suitable for high-intensity applications that generate significant heat.

Unique Features of K-COB Technology

Innovative Material Use

K-COB technology sets itself apart by replacing traditional organic materials like epoxy or silicone with a self-developed phosphor ceramic, also known as a ceramic phosphor converter. This innovative material enhances the durability and performance of COB LEDs, making them more resilient to environmental factors and mechanical stress. The use of phosphor ceramic also improves the light quality and consistency, ensuring superior performance in demanding applications.

Enhanced Thermal Performance

The combination of Copper PCB and phosphor ceramic in K-COB LEDs ensures superior heat dissipation, which is crucial for maintaining efficiency and longevity in high-power applications. The advanced thermal management of K-COB technology allows the LEDs to operate at higher power levels without compromising performance or reliability. This makes K-COB LEDs ideal for applications like sports lighting, searchlights, and TV & film lighting, where high-intensity illumination is required.

Benefits for High-Power Lighting Applications

K-COB LEDs offer several advantages for high-power lighting applications. Their high lumen output and uniform light distribution make them perfect for sports arenas, ensuring clear visibility and enhancing the experience for both players and spectators. The intense and focused beam of K-COB LEDs is also ideal for searchlights used in rescue operations, law enforcement, and other critical missions. Additionally, the consistent color temperature and high color rendering index (90RA) of K-COB LEDs make them essential for producing high-quality visual content in film and television production.

Choosing the Right COB vs LED for Your Project

When selecting COB LEDs for your project, it is essential to consider the specific requirements of your application. Power requirements are a critical factor, with different COB LEDs offering varying power ratings, such as 800W, 1000W, and 1200W. Higher power options are suitable for large-scale and professional setups, ensuring adequate illumination for demanding environments.

Color temperature and rendering are also important considerations. For applications requiring natural light, such as TV & film lighting, COB LEDs with a color temperature of 5000K and a high color rendering index (90RA) ensure accurate color rendering and pleasant light quality. This enhances the visual experience and ensures the highest quality lighting for your project.

Benefits of Partnering with CAS-CERAMIC OPTOELECTRONICS TECHNOLOGY CO., Ltd

Quality and Reliability

Partnering with a reputable COB vs LED manufacturer like CAS-CERAMIC OPTOELECTRONICS TECHNOLOGY CO., Ltd ensures that you receive high-quality products that meet industry standards such as LM-80 certification. This guarantees long-term performance and reliability, giving you confidence in the durability and efficiency of your lighting system.

Customization and Support

Top manufacturers offer customization options to meet the specific requirements of your project. CAS-CERAMIC OPTOELECTRONICS TECHNOLOGY CO., Ltd provides tailored solutions and technical support to ensure the successful implementation of your lighting system. This personalized approach helps you achieve the best possible results for your project.

Economic Efficiency

Investing in high-quality COB LEDs from a reputable manufacturer reduces energy costs and maintenance over time. The superior performance and efficiency of COB LEDs translate into long-term savings, making them a cost-effective solution for high-power lighting applications.

Conclusion

Choosing between COB and traditional LEDs depends on the specific requirements of your lighting project. For high-power, high-intensity applications such as sports, search, and TV & film lighting, COB LEDs, particularly those utilizing K-COB technology, offer unmatched performance and reliability. Partnering with a reputable manufacturer like CAS-CERAMIC OPTOELECTRONICS TECHNOLOGY CO., Ltd ensures you receive high-quality products tailored to your needs, guaranteeing the success and efficiency of your lighting installations. By understanding the differences and advantages of COB and traditional LED technologies, purchasing departments and wholesale buyers can make informed decisions that enhance the quality and performance of their lighting systems.

Post time: Jul-11-2024