Understanding the Importance of LED Reliability

When it comes to LED lights, their stability and performance rely heavily on the reliability of the light source itself. In an increasingly competitive market, the quality of LED products can often be the deciding factor for customers. But what exactly sets the best LED lights apart from the rest? The answer lies in the heart of the LED itself: the chip. Among the most advanced solutions today is the K-Chip COB – a breakthrough in LED technology that promises to address many of the long-standing issues in the industry.

In this blog, we will explore the key challenges faced by the LED industry, and how CAS-Ceramic Optoelectronics Technology Co., Ltd. is revolutionizing the LED lighting market with their K-COB chip.

The Rise of K-COB Technology

What is Chip COB (Chip-on-Board) Technology?

Chip-on-Board (COB) is a type of LED packaging technology that directly attaches LED chips to a substrate or PCB (Printed Circuit Board) without using a separate package or casing. This design allows for better thermal management, higher light output, and increased reliability compared to traditional LED packaging methods.

What is K-COB?

The K-COB chip is a next-generation LED technology developed by CAS-Ceramic Optoelectronics Technology Co., Ltd. It introduces a unique LED packaging pattern by replacing traditional materials like epoxy or silicone—commonly used in white LEDs—with a self-developed phosphor ceramic (or ceramic phosphor converter).

Phosphor ceramic, when used in LED applications, offers significant advantages over traditional materials. It boasts a much lower thermal resistance compared to epoxy and silicone, which means the chip can operate at higher efficiencies without the risk of overheating. This results in a longer lifespan and improved performance under extreme conditions. The ceramic material also provides a harder surface, making it impact-resistant and better able to withstand temperature and humidity fluctuations.

Why Is K-COB a Game-Changer?

One of the main challenges for traditional LEDs is the heat management. The materials used in conventional LED packaging, such as epoxy and silicone, are not as effective at dissipating heat. This often leads to thermal degradation, where the phosphor layer begins to degrade over time due to excessive heat. The result? Reduced brightness, color shifts, and ultimately, failure of the LED.

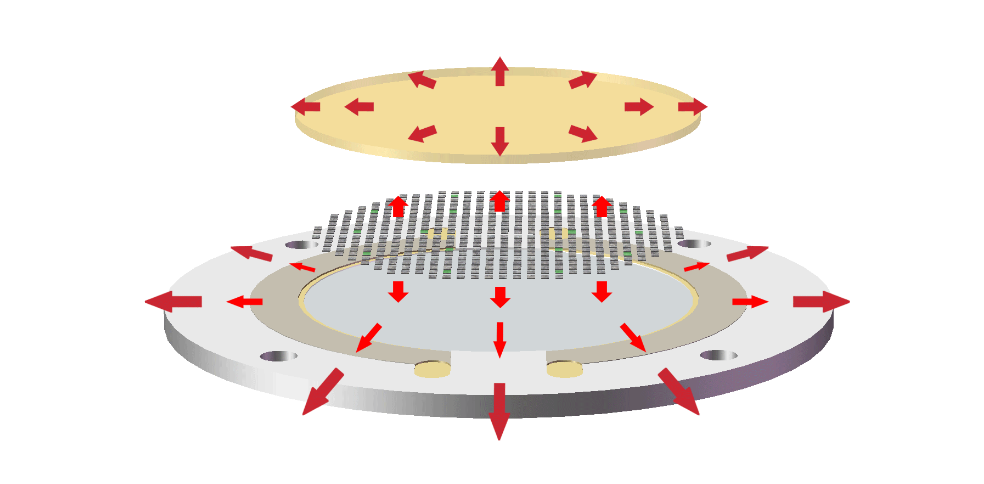

K-COB solves this issue with its patented “dual channel heatsinking” structure, which allows heat to dissipate both from the ceramic cover and the PCB (Printed Circuit Board) via sapphire. This heat management innovation helps K-COB achieve higher light density and lumen intensity, as well as superior reliability. The LM-80 certification for K-COB ensures that it can sustain its performance even in high temperatures, making it an ideal choice for demanding applications.

Key Challenges in the LED Lighting Industry

Challenge #1: Thermal Management Issues in Traditional LEDs

LED lights are known for their energy efficiency, but when it comes to high-power applications, heat dissipation becomes a major challenge. Traditional LED chips, especially those made with epoxy or silicone, struggle to dissipate heat efficiently. As a result, these chips can overheat, leading to thermal degradation and a shortened lifespan.

K-COB’s Solution

The K-Chip COB addresses this issue with its innovative dual heatsinking system. By incorporating both ceramic and sapphire materials into the heatsinking structure, K-COB significantly reduces thermal resistance. This ensures that the chip stays cooler, even during extended use, resulting in improved longevity and better performance. With K-COB, you get a reliable LED light source that can handle higher power applications without compromising on efficiency.

Challenge #2: Phosphor Degradation and Color Shifting

Phosphor degradation is a common issue with traditional LEDs. As the phosphor material ages over time, the color temperature and brightness of the LED can degrade, causing color shifts and reduced lumen output. This is particularly problematic in high-demand industries such as street lighting and sports lighting.

K-COB’s Solution

The K-Chip COB uses phosphor ceramic, which is much more stable than the traditional organic phosphor used in other LEDs. Unlike silicone or epoxy, phosphor ceramic does not age or degrade over time. This means that K-COB maintains its color consistency and lumen intensity for a much longer period, ensuring a stable and reliable light output throughout its lifespan.

Challenge #3: Vulnerability to Environmental Factors

LEDs are often exposed to harsh environmental conditions, including high humidity, temperature fluctuations, and exposure to chemicals. Traditional LED packaging materials like epoxy and silicone can break down or corrode over time when exposed to these factors, leading to performance degradation and failure.

K-COB’s Solution

One of the standout features of the K-COB chip is its resilience to environmental factors. The phosphor ceramic material used in K-COB is highly resistant to temperature and humidity fluctuations, as well as to chemical corrosion. This makes K-COB a highly durable option for outdoor applications, such as high-mast lighting, sports lighting, and street lighting, where exposure to the elements is a constant concern.

Challenge #4: Inconsistent Light Output and Low Lumen Density

In many LED applications, the light output and lumen density can vary significantly between different manufacturers and models. Inconsistent light output not only reduces the aesthetic appeal of lighting solutions but also negatively impacts their functionality. For example, streetlights or floodlights with low lumen density may fail to provide adequate illumination.

K-COB’s Solution

The K-Chip COB offers higher light density than traditional COB LEDs. With a smaller light-emitting size (LES), K-COB achieves greater lumen intensity while maintaining energy efficiency. The ceramic phosphor material ensures that the light output remains consistent, while the dual-channel heat sinking guarantees that the chip continues to operate at optimal efficiency, even in high-power applications.

Challenge #5: High Production Costs for Advanced LED Technologies

Advanced LED technologies that offer superior performance often come with a high price tag, which can make them less accessible for many customers. Traditional materials, like silicone and epoxy, are relatively inexpensive, but they come with significant trade-offs in terms of reliability and longevity.

K-COB’s Solution

CAS-Ceramic Optoelectronics Technology Co., Ltd. has invested years of research into optimizing phosphor ceramic for LED applications. Their self-invented phosphor ceramic is not only superior in terms of thermal conductivity and lighting efficacy but also offers cost-effective manufacturing. By streamlining production and leveraging their patented technologies, CAS-Ceramic has been able to offer K-COB chips at a competitive price without compromising on performance or reliability.

Why Choose CAS-Ceramic for Your LED Lighting Needs?

CAS-Ceramic Optoelectronics Technology Co., Ltd. is setting new standards in the LED lighting industry with their innovative K-COB chip technology. As the only manufacturer that mass-produces high-power COB LEDs with LM-80 certification, they offer unmatched reliability, performance, and cost-effectiveness.

Key Advantages of CAS-Ceramic’s K-COB

Superior Thermal Management: The patented dual-channel heat sinking structure ensures that heat is effectively dissipated, leading to better performance and a longer lifespan.

Long-Term Reliability: The phosphor ceramic material never degrades, offering consistent light output over time.

High Light Density and Efficiency: K-COB offers up to 30% higher light density compared to traditional COB LEDs.

Durability: The impact-resistant ceramic and moisture-resistant properties make K-COB ideal for a wide range of applications, from street lighting to sports lighting.

Competitive Pricing: Despite its advanced technology, K-COB is offered at a competitive price, making it accessible to a wider range of customers.

Conclusion: The Future of LED Lighting is Here

The LED industry is evolving, and with it, the demand for more reliable, efficient, and cost-effective lighting solutions. The K-Chip COB from CAS-Ceramic Optoelectronics Technology Co., Ltd. represents a significant leap forward in LED technology, addressing key challenges such as thermal management, phosphor degradation, and environmental resistance. With its superior performance and innovative design, K-COB is poised to lead the way in the next generation of LED lighting. If you’re looking for a high-performance, long-lasting, and environmentally resilient LED solution, K-COB is the answer.

Choose CAS-Ceramic for your LED needs and experience the future of lighting today.

Post time: Nov-26-2024