CAS CERAMIC, a leading LED manufacturer affiliated with the Chinese Academy of Sciences, stands at the forefront of innovation in lighting technology. Renowned for its commitment to advancement, CAS CERAMIC specializes in the development, engineering, and manufacturing of cutting-edge LED chips, particularly the revolutionary phosphor ceramic COB, aptly named K-COB. This groundbreaking technology boasts patented advancements, representing a paradigm shift in the industry. The Ceramic LED Chip not only signifies a leap forward in efficiency and durability but also underscores CAS CERAMIC’s dedication to pushing the boundaries of what is possible in contemporary lighting solutions.

The Evolution of LED Technology

Historical Context of LED Development:

The journey of LED technology traces back to its rudimentary applications as simple indicators. Over the years, this once-modest technology has evolved against the backdrop of technological progress and market demands. From its inception as a basic signaling device, LEDs have evolved into sophisticated lighting solutions, with each developmental phase contributing to enhanced functionality and broader applications.

Advancements Leading to CAS CERAMIC

CAS CERAMIC’s role in the evolution of LED technology is characterized by groundbreaking advancements. At the forefront is the patented “dual channel heat sinking” structure, a technological milestone that facilitates efficient heat dissipation from both the ceramic and the printed circuit board (PCB). This innovative design not only ensures better reliability but also extends the lifespan of the LED chip. CAS CERAMIC’s commitment to excellence is further evidenced by the acquisition of five international invention patents, underscoring the company’s pioneering spirit. With an extensive portfolio of patents and certifications, CAS CERAMIC stands as a beacon of innovation. Notably, as the exclusive supplier with LM80 certification for high-power COB, CAS CERAMIC reaffirms its position as a leader in advancing the capabilities and standards of LED technology.

Unveiling CAS CERAMIC LED Chip

Key Features and Specifications

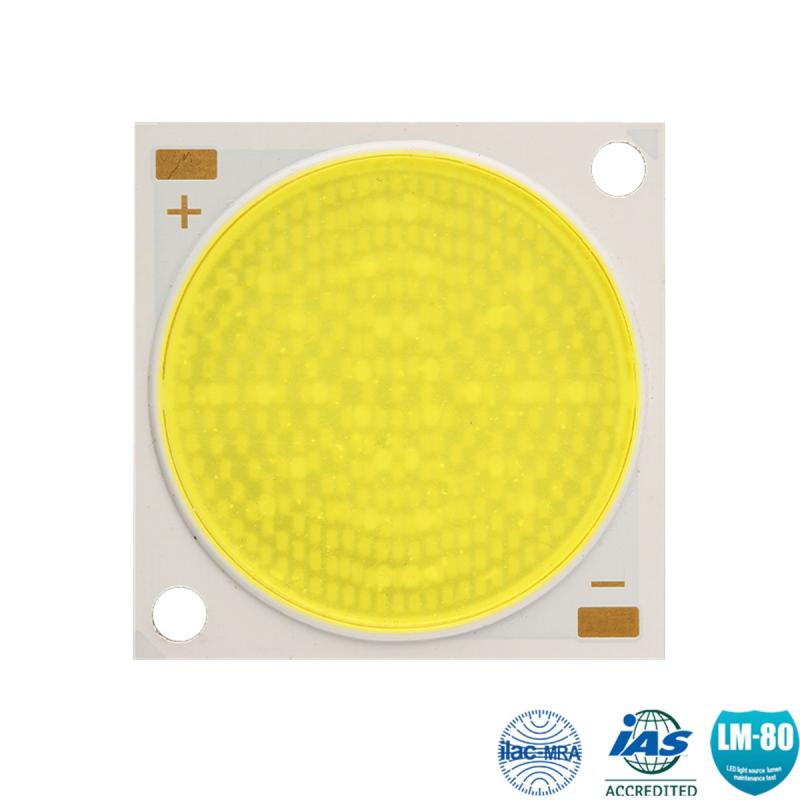

CAS CERAMIC LED Chip introduces a paradigm shift in lighting technology with its remarkable features and specifications. Notably, its small Light-Emitting Size (LES) sets the stage for precise and efficient spotlighting, making it an ideal choice for applications such as 200W and 100W COB LED configurations. The emphasis on good heat dissipation is embodied in the patented “dual heatsinking channel” structure, ensuring optimal thermal performance and guaranteeing reliability.

Innovative Design Elements

At the heart of CAS CERAMIC’s LED Chip is the groundbreaking design that combines small LES with a robust spotlighting capability. The patented “dual heatsinking channel” structure is a testament to the company’s commitment to innovation. This design not only addresses the challenges of heat dissipation effectively but also contributes to the overall longevity and durability of the LED chip. The focus on customization is another standout feature, allowing users to tailor Color Correlated Temperature (CCT), Color Rendering Index (CRI), as well as Forward Current (If) and Forward Voltage (Vf) to meet specific demands.

Comparative Advantages Over Traditional LED Chips

CAS CERAMIC LED Chip establishes itself as a frontrunner by offering unparalleled advantages compared to traditional LED chips. The small LES and spotlighting capabilities make it particularly suitable for high-power applications like 200W and 100W COB LED configurations. The patented “dual heatsinking channel” structure not only guarantees superior heat dissipation but also sets a new standard for thermal performance and chip reliability. Approved by LM80 for high lumen intensity, CAS CERAMIC LED Chip surpasses traditional alternatives, making it a versatile and efficient choice for various applications, including high bay lighting, street lights, retrofit kits, and beyond.

Cutting-Edge Technology

Explanation of Ceramic Material in LED Technology

CAS CERAMIC’s K-COB introduces a distinctive LED packaging innovation by substituting conventional organic materials, such as epoxy or silicone, with a proprietary self-developed phosphor ceramic. This groundbreaking material, also known as a ceramic phosphor converter, redefines the composition of white LEDs, marking a significant departure from traditional packaging methods.

Technical Advancements Contributing to Performance

The key to K-COB’s superior performance lies in the application of phosphor ceramic. This material boasts significantly lower thermal resistance compared to the molding of epoxy and silicone. The unique characteristics of phosphor ceramic, including a hard surface, impact resistance, and robust tolerance to temperature and humidity fluctuations, contribute collectively to elevate the overall performance and reliability of CAS CERAMIC’s LED chip.

Sustainability and Environmental Benefits:

Beyond its technical prowess, CAS CERAMIC’s adoption of phosphor ceramic holds notable sustainability and environmental benefits. The material’s durability, impact resistance, and resilience to environmental changes contribute to the extended lifespan of the LED chip. This longevity, coupled with the reduction in thermal resistance, not only enhances the chip’s performance but also aligns with eco-friendly practices by minimizing electronic waste. CAS CERAMIC thus emerges as a trailblazer in sustainable LED technology, offering a cutting-edge solution with positive implications for both performance and the environment.

Applications and Versatility

Range of Applications for CAS CERAMIC

CAS CERAMIC’s LED technology transcends traditional boundaries, offering a versatile solution applicable across a broad spectrum of lighting needs. From high bay luminaires to streetlights and retrofit kits, the adaptability of CAS CERAMIC LED Chip spans various lighting configurations, showcasing its versatility in meeting diverse illumination requirements.

Versatility in Various Industries

The versatility of CAS CERAMIC finds expression in its seamless integration across multiple industries. Whether illuminating expansive industrial spaces, enhancing street lighting infrastructure, or facilitating energy-efficient retrofits, CAS CERAMIC LED Chip proves instrumental in elevating lighting standards across diverse sectors, from manufacturing and infrastructure to urban development and beyond.

Real-World Examples and Success Stories

Real-world applications highlight the success of CAS CERAMIC in delivering practical and efficient lighting solutions. From large-scale industrial complexes experiencing improved visibility to municipalities benefiting from energy-saving street lighting, the tangible impact of CAS CERAMIC is evident in the success stories of those who have embraced its innovative LED technology.

Performance and Efficiency

Energy Efficiency and Cost-Effectiveness

CAS CERAMIC LED Chip stands as a beacon of energy efficiency, providing substantial cost savings to end-users. Its innovative design, coupled with advanced phosphor ceramic technology, ensures optimal light output with minimal energy consumption. This emphasis on energy efficiency translates directly into cost-effectiveness, making CAS CERAMIC an economically sound choice for lighting applications.

Longevity and Durability of CAS CERAMIC

The longevity and durability of the CAS CERAMIC LED Chip set it apart in the realm of lighting technology. The unique “dual heatsinking channel” structure and the use of phosphor ceramic contribute to a longer lifespan, reducing the frequency of replacements. This durability not only enhances the overall performance but also minimizes maintenance costs, providing a sustainable and cost-effective lighting solution.

Performance Benchmarks and Test Results

CAS CERAMIC’s commitment to excellence is validated through rigorous performance testing and benchmark assessments. The LED chip’s adherence to LM80 standards for high lumen intensity, combined with its innovative design, showcases superior performance. Test results underscore its reliability, efficiency, and consistency, offering users a product that not only meets but exceeds industry standards.

Environmental Impact

CAS CERAMIC’s Contribution to Sustainability

CAS CERAMIC is at the forefront of sustainable lighting solutions, contributing significantly to environmental stewardship. Its LED technology aligns with sustainable practices by maximizing energy efficiency, minimizing waste, and promoting a longer product lifecycle. CAS CERAMIC’s commitment to sustainability goes beyond mere compliance, actively contributing to a greener and more sustainable future.

Reduced Carbon Footprint Compared to Traditional Alternatives

Choosing CAS CERAMIC means choosing a reduced carbon footprint. Compared to traditional alternatives, the energy-efficient and durable nature of CAS CERAMIC LED Chip minimizes environmental impact, making it an eco-conscious choice for individuals, businesses, and municipalities looking to mitigate their carbon footprint.

Eco-Friendly Manufacturing Processes

CAS CERAMIC prioritizes eco-friendly manufacturing processes, ensuring that the production of its LED chips aligns with sustainable practices. From material selection to manufacturing techniques, CAS CERAMIC is dedicated to minimizing its environmental footprint. The result is a product that not only excels in performance but also champions environmentally conscious practices in the manufacturing industry.

Embrace CAS CERAMIC’s Ceramic LED Chip for a Sustainable Lighting Revolution!

CAS CERAMIC’s Radiant Innovation in unveiling the Ceramic LED Chip represents a transformative leap in lighting technology. With its pioneering phosphor ceramic COB, innovative design, and commitment to sustainability, CAS CERAMIC sets a new standard for efficiency, versatility, and environmental responsibility. Embracing the Ceramic LED Chip signifies not only a commitment to cutting-edge illumination but also a bold step towards a brighter, more sustainable future in the world of lighting.

Post time: Dec-07-2023