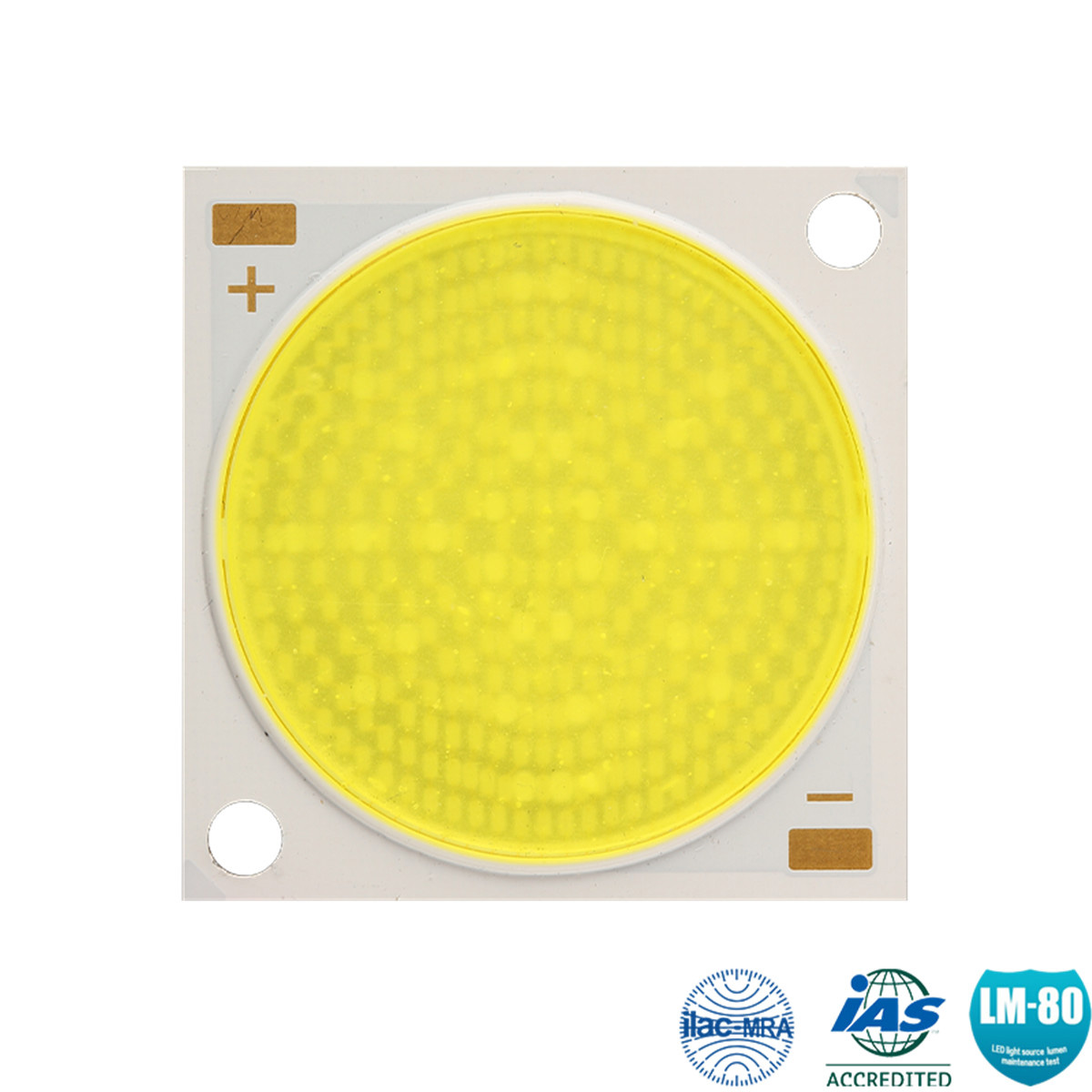

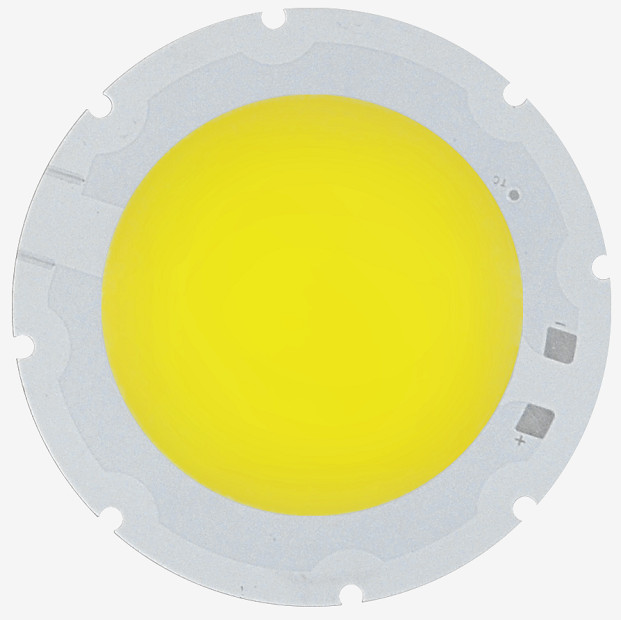

Wholesale cob led chips 50w 100w 200w 300w 600w 1000w 1200w for COB LED lighting solution

What is the difference between LED and K-COB LED?

LED (light-emitting diode) is now a very common technology today. With the advantages of low energy consumption, long life-span, and instant start-up, the fixture with LED light source has replaced the traditional MHL (metal halide lamp) and HPS(high-pressure sodium) lamp on the market gradually.

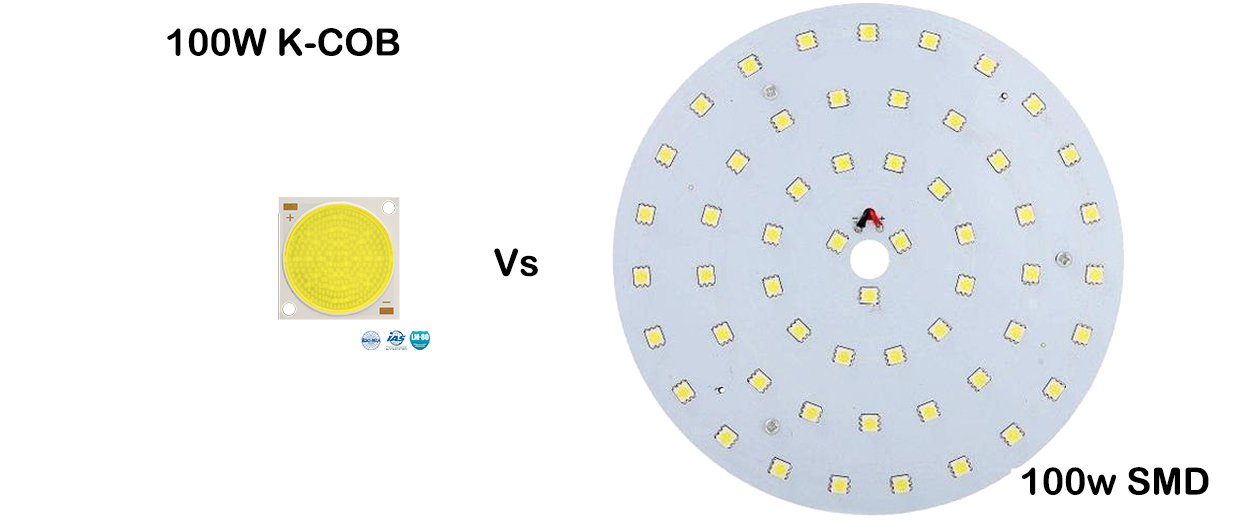

LED is used to divide into SMD(surface mounting device) and COB(chip on board), the biggest difference between LED COB and SMD is that COB has times more diode in the same PCB surface. It means the COB chip has a higher light density, directivity, and enhanced optical control. And this is the reason why COB is popular in high mast lighting areas such as stadium lighting, search lighting, port lighting .,etc.

The application of high power cob led chips

Large space Lighting (football court/golf resort/stadium court)

Long-distance lighting-Searchlight for ship/tugs

Special lighting for high reliability requirements( underwater fishing lamp,overhaed fishing lights)

LM 80 TEST REPORT AND 4 CORE PATENT CERTIFICATE

Why the K-COB LED CHIPS are the best choice of lighting fixture?

But the high diode/light density feature is a double-edged sword, as the benefits it brings, it also causes a big headache in heatsinking. The heat generated from diodes is so centralized that a normal SMD heatsink is not able to dissipate. It finally results in the failure of the diode and fluorescent material (usually the mixture of phosphor&epoxy/silicone )

If there is a fluorescent LED packaging material with good thermal resistance and physical properties, then all the pain points above could be resolved.

And this is the reason we developed the phosphor ceramic and make K-COB.

Phosphorus ceramic is developed by FUJIAN CAS-CERAMIC OPTOELECTRONICS TECHNOLOGY CO ., Ltd. It has outstanding thermal conductivity and temperature resistance, a perfect up-gradation for traditional phosphor material in LED chips.

Small light-emitting size(LES), high light density, easy optical design;

Do K-COB get hot?

K-COB LED CHIPS has patented dual-channel heat sink technology. The phosphor ceramic provides additional heat conductive channels. The heat dissipates from the top of the phosphor ceramic and the bottom of the PCB board. The K-COB led chips with high reliability and high performance of light intensity due to the heat sink are better than common led chips.

We separate two main heat source of LED diode and phosphor by this dual heatsinking channel design. And it helps to the reduction of chip junction temperature effectively.

Specification

|

Item No. |

Rated Power(W) |

Forward Voltage Vf(V) |

Rated Currency If(MA) |

Max Input Currency(MA) |

CRI(Ra) |

CCT(K) |

Efficacy Im/W Based On 70ra |

|

XY-L2805 |

50 |

49 |

1020 |

2600 |

70/80/90 |

2000-6500 |

165lm/w |

|

XY-L2810 |

100 |

49 |

2000 |

2600 |

70/80/90 |

2000-6500 |

160lm/w |

|

XY-L2815 |

150 |

49 |

3050 |

3150 |

70/80/90 |

2000-6500 |

150lm/w |

|

XY-L3815 |

150 |

59 |

2400 |

2550 |

70/80/90 |

2000-6500 |

165lm/w |

|

XY-L3820 |

200 |

59 |

3150 |

3250 |

70/80/90 |

2000-6500 |

160lm/w |

|

XY-L3830 |

300 |

105 |

2700 |

2850 |

70/80/90 |

2000-6500 |

150lm/w |

|

Item No. |

Rated Power(W) | Forward Voltage Vf(V) | Rated Currency IF(MA) | Max Input Currency(MA) | CRI(Ra) | Color Temperature(K) | Efficiency Im/WBased On 70ra |

|

XY-L4730 |

300 |

105 |

2700 |

2850 |

70/80/90 |

2000-6500 |

165lm/w |

|

XY-L4740 |

400 |

105 |

3600 |

3800 |

70/80/90 |

2000-6500 |

160lm/w |

|

Item No. |

Rated Power(W) |

Forward Voltage Vf(V) |

Rated Currency IF(mA) |

Max Input currency(mA) |

CRI(Ra) |

Color Temperature(K) |

Efficiency Im/w Based on 70ra |

|

XY-L5640 |

400 |

124 |

3000 |

3150 |

70/80/90 |

2000-6500 |

165lm/w |

|

XY-L5650 |

500 |

124 |

3700 |

4050 |

70/80/90 |

2000-6500 |

160lm/w |

|

XY-L5660 |

600 |

124 |

4300 |

4800 |

70/80/90 |

2000-6500 |

155lm/w |

|

XY-L5670 |

700 |

124 |

5300 |

5500 |

70/80/90 |

2000-6500 |

150lm/w |

|

Item No. |

Rated Power(W) |

Forward Voltage Vf(V) |

Rated Currency IF(MA) |

Max Input Currency(MA) |

CRI(Ra) |

Color Temperature(K) |

Efficiency Im/W Based On 70ra |

|

XY-L6580 |

800 |

333 |

2400 |

3900 |

70/80/90 |

2000-6500 |

165lm/w |

|

XY-L65100 |

1000 |

333 |

3000 |

3900 |

70/80/90 |

2000-6500 |

160lm/w |

|

XY-L75120 |

1200 |

333 |

3600 |

3900 |

70/80/90 |

2000-6500 |

165lm/w |

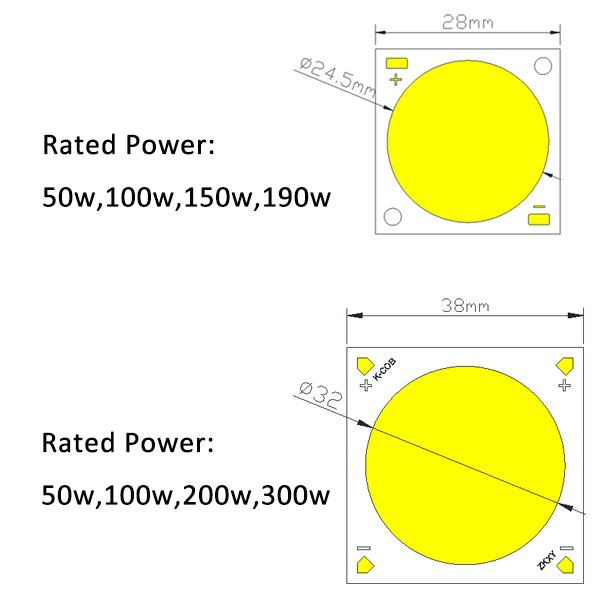

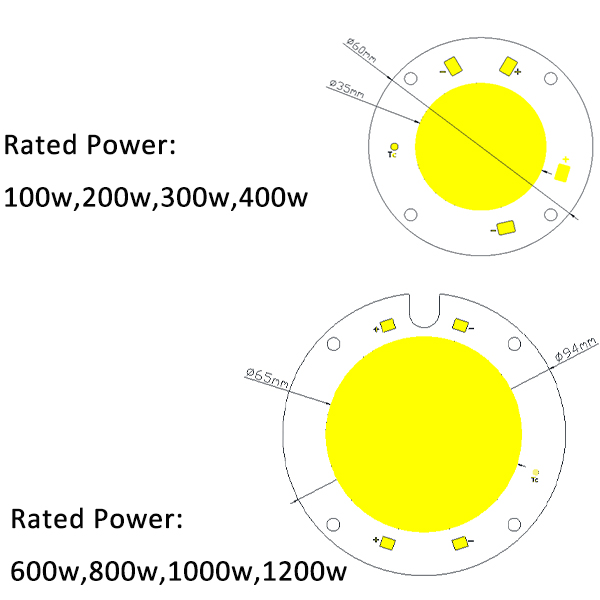

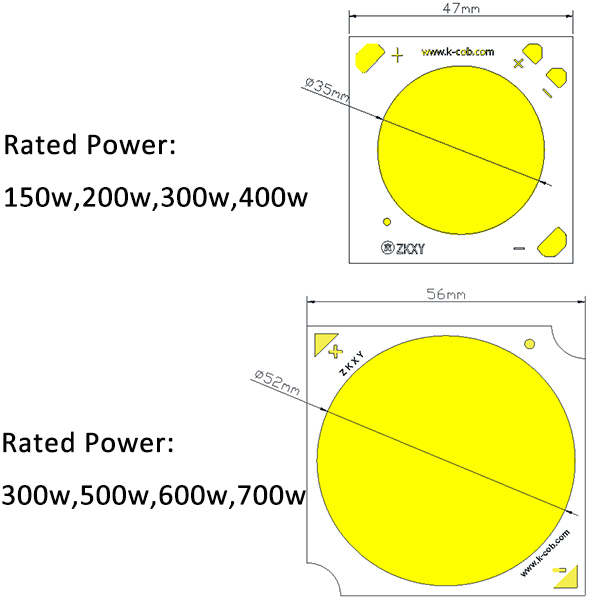

DIMENSIONS DRAWING

*Size & Circuit is customizable based on the requirement

How do you wire LED COBs?

1. Apply an appropriate amount of thermal grease to the bottom of the lamp housing

2. Put the lamp bead on the place where thermal grease is applied

3. Weld the wires to the positive and negative poles of the lamp beads

4. Put the corresponding bracket on the lamp bead, (note: the yellow part cannot be pressed)

5. Fix the bracket with screws

6. Screw the lamp cover of the lamp, and the installation is finished.

What’s the price of K-cob led chips?

Different from traditional silica gel COB and SMD light sources, phosphor ceramic COB is a new generation of light sources with higher light intensity and safer and more reliable quality. Since K-COB LED adopts self-developed technology, we already have a mature technology and own serval production line, compared with international big brands cree, bridglux, citizen, our cost performance is higher. If you need, you can leave us a message, our lighting experts will give you a professional reply within 24 hours.

K-COB (Maximum power for single chip could reach 1600w)

K-COB LED arrays provide the industry’s best lumen density and efficacy for metal-based chip-on-board (COB) LEDs in industry-compatible footprints and LES sizes. This COB family features an innovative exclusive patent phosphor ceramic technology as well as dual heat-sink technology to deliver higher reliability and output than competing products. The K-COB LED arrays include 10 LEDs across three (9.8 mm, 14.5 mm and 22 mm) LES sizes with standard color options of 70, 80 and 90 CRI. Premium color options that include high fidelity (98 CRI) and specialty color points are available to deliver color quality without compromise in efficacy, lumen density, color consistency and reliability.

The K-COB Series is a comprehensive range of metal-based COBs available in various LES, CRI, CCT, efficacy, and drive current options. The heat could be radiating from both PCB directly and laser ceramic surface by sapphire.

This dual heatsinking structure allow us make COB at smaller size but higher wattage and better reliability.

The Phosphor ceramic is the high heat conductivity rate: 13.367W/m.k, 75 times of traditional phosphorus powder (YAG 05+sil1018), which ensures excellent lumen maintenance and color stability even in high lumen applications. Tight color binning ensures fixture-to-fixture uniformity. A 97 CRI (90 R9) version is available for color-critical applications.

Please contact send us an email to ask for more recommendations, help and advice for your lighting projects