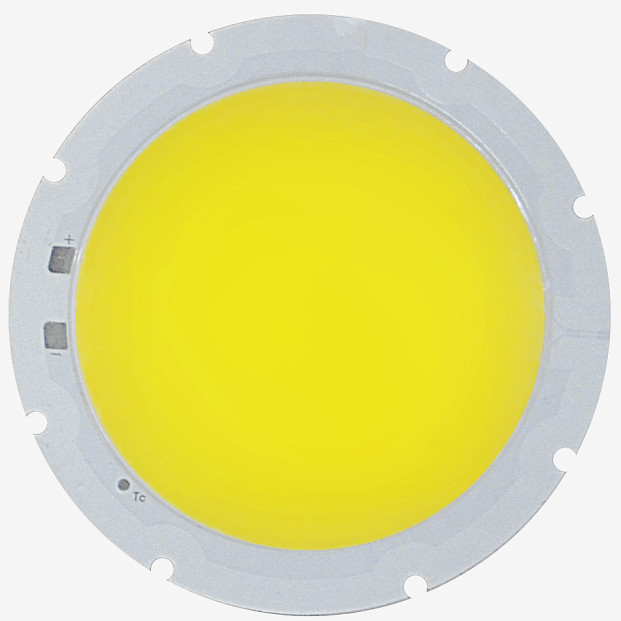

Phosphor Ceramic 6500k cri 90 led lights Source 1200W XY-L75 SERIES

Specification

|

Item No. |

Rated Power(W) |

Forward Voltage Vf(V) |

Rated Currency IF(mA) |

Max Input currency(mA) |

CRI(Ra) |

Color Temperature(K) |

Efficiency Im/w Based on 70ra |

|

XY-L75120 |

1200 |

333 |

3600 |

3900 |

70/80/90 |

2000-6500 |

165lm/w |

Brand: K-COB

Rated Power: 1200w

Forward voltage:333v

Rated currency: 3600mA

CR:70ra,80ra,90ra

Efficiency:150lm/w

Temperature Color: Warm White (3000~3500K), Cool White (6000~6500K)

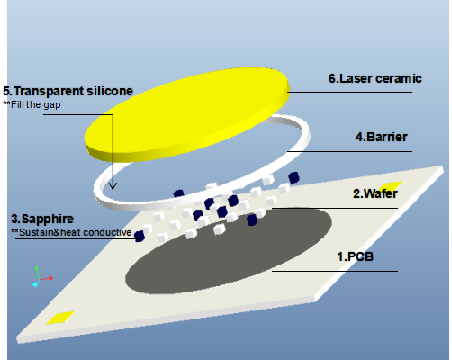

We use special laser ceramic(patented)as core packing material, and packaging with our exclusive 3D packaging pattern: using particular sapphire as sustainment&heat conductive path.

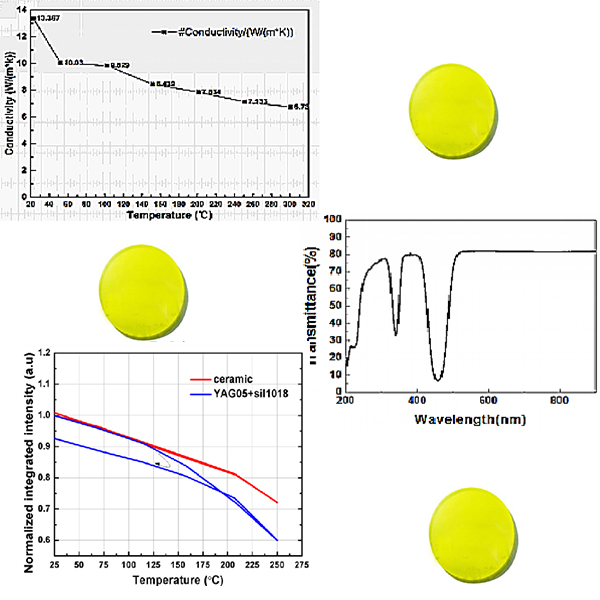

Advantages of Laser-ceramic:

- One of the main advantages of the laser ceramic is a high heat conductivity rate: 13.367W/m.k, 75 times of traditional phosphorous powder (YAG05+sil1018).

- Small lattice spacing and near single molecule structure will bring less lumen loss and higher reliability;

- Hard surface, impact-proof, and also good resistance to temperature& acidity, and alkalinity change.

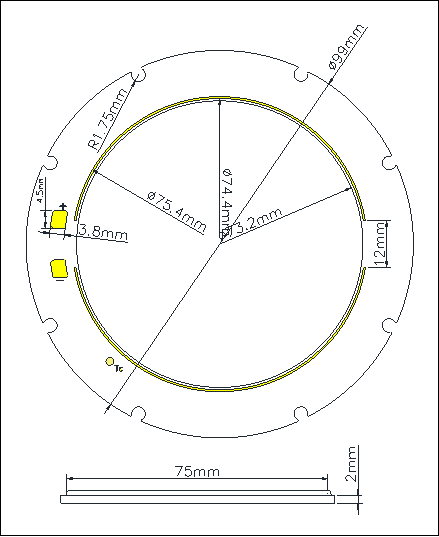

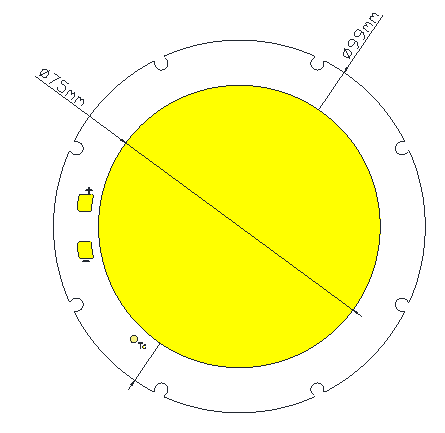

DIMENSIONS DRAWING

*Size & Circuit is customizable based on the requirement

LED WORKSHOP

*Size & Circuit is customizable based on the requirement

K-COB (Maximum power for single chip could reach 1600w)

K-COB LED arrays provide the industry’s best lumen density and efficacy for metal-based chip-on-board (COB) LEDs in industry-compatible footprints and LES sizes. This COB family features an innovative exclusive patent phosphor ceramic technology as well as dual heat-sink technology to deliver higher reliability and output than competing products. The K-COB LED arrays include 10 LEDs across three (9.8 mm, 14.5 mm and 22 mm) LES sizes with standard color options of 70, 80 and 90 CRI. Premium color options that include high fidelity (98 CRI) and specialty color points are available to deliver color quality without compromise in efficacy, lumen density, color consistency and reliability.

The K-COB Series is a comprehensive range of metal-based COBs available in various LES, CRI, CCT, efficacy, and drive current options. The heat could be radiating from both PCB directly and laser ceramic surface by sapphire.

This dual heatsinking structure allow us make COB at smaller size but higher wattage and better reliability.

The Phosphor ceramic is the high heat conductivity rate: 13.367W/m.k, 75 times of traditional phosphorus powder (YAG 05+sil1018), which ensures excellent lumen maintenance and color stability even in high lumen applications. Tight color binning ensures fixture-to-fixture uniformity. A 97 CRI (90 R9) version is available for color-critical applications.

Please contact send us an email to ask for more recommendations, help and advice for your lighting projects