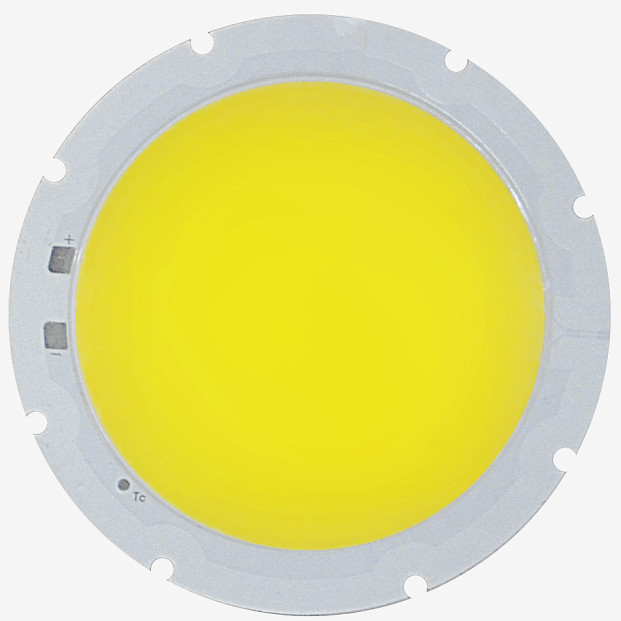

Cob Lighting Factory – Wholesale cob led chips 50w-1200w for high power led fixture – CAS-Ceramic

Cob Lighting Factory – Wholesale cob led chips 50w-1200w for high power led fixture – CAS-Ceramic Detail:

What is the difference between LED and K-COB LED?

LED (light-emitting diode) is now a very common technology today. With the advantages of low energy consumption, long life-span, and instant start-up, the fixture with LED light source has replaced the traditional MHL (metal halide lamp) and HPS(high-pressure sodium) lamp on the market gradually.

LED is used to divide into SMD(surface mounting device) and COB(chip on board), the biggest difference between LED COB and SMD is that COB has times more diode in the same PCB surface. It means the COB chip has a higher light density, directivity, and enhanced optical control. And this is the reason why COB is popular in high mast lighting areas such as stadium lighting, search lighting, port lighting .,etc.

The application of high power cob led chips

LM 80 TEST REPORT AND 4 CORE PATENT CERTIFICATE

Do K-COB get hot?

K-COB LED CHIPS has patented dual-channel heat sink technology. The phosphor ceramic provides additional heat conductive channels. The heat dissipates from the top of the phosphor ceramic and the bottom of the PCB board. The K-COB led chips with high reliability and high performance of light intensity due to the heat sink are better than common led chips.

We separate two main heat source of LED diode and phosphor by this dual heatsinking channel design. And it helps to the reduction of chip junction temperature effectively.

Specification

|

Item No. |

Rated Power(W) |

Forward Voltage Vf(V) |

Rated Currency IF(mA) |

Max Input currency(mA) |

CRI(Ra) |

Color Temperature(K) |

Efficiency Im/w Based on 70ra |

|

XY-L5640 |

400 |

124 |

3000 |

3150 |

70/80/90 |

2000-6500 |

165lm/w |

|

XY-L5650 |

500 |

124 |

3700 |

4050 |

70/80/90 |

2000-6500 |

160lm/w |

|

XY-L5660 |

600 |

124 |

4300 |

4800 |

70/80/90 |

2000-6500 |

155lm/w |

|

XY-L5670 |

700 |

124 |

5300 |

5500 |

70/80/90 |

2000-6500 |

150lm/w |

DIMENSIONS DRAWING

*Size & Circuit is customizable based on the requirement

How do you wire LED COBs?

1. Apply an appropriate amount of thermal grease to the bottom of the lamp housing

2. Put the lamp bead on the place where thermal grease is applied

3. Weld the wires to the positive and negative poles of the lamp beads

4. Put the corresponding bracket on the lamp bead, (note: the yellow part cannot be pressed)

5. Fix the bracket with screws

6. Screw the lamp cover of the lamp, and the installation is finished.

What’s the price of K-cob led chips?

Different from traditional silica gel COB and SMD light sources, phosphor ceramic COB is a new generation of light sources with higher light intensity and safer and more reliable quality. Since K-COB LED adopts self-developed technology, we already have a mature technology and own serval production line, compared with international big brands cree, bridglux, citizen, our cost performance is higher. If you need, you can leave us a message, our lighting experts will give you a professional reply within 24 hours.

K-COB LED CHIPS RELATED PRODUCTS

Product detail pictures:

Related Product Guide:

KCOB invent high power cob led lights as well as area lights at the request of our customers.Our team of dedicated project managers, program designers, technology experts, marketing strategists and logistics leaders are deeply committed to delivering impact for our customers and our planet.Many departments work together to manage our commercial lights from outlook of the lights fixtures to specifictaion of the lights. Cob Lighting Factory – Wholesale cob led chips 50w-1200w for high power led fixture – CAS-Ceramic , The product will supply to all over the world, such as: Sri Lanka, Malaysia, US, Who is KCOB? KCOB is a One&only LED LASER CERAMIC COB manufacturer in China. a COB chip made by special packaging pattern: a particular combination of PCB, blue chip&patented laser ceramic.What is the features? 1. High lumen density: longer lighting distance&illuminance; 2. Better heat reliability: heat sinking by both PCB and ceramic surface, 0% lumen decay in 5 years: ;3. Hard surface: impact proof to temperature&humidity;What is the use of COB?We make our own lamp with it too,which is including the Artificial lighting,industrial lighting, led commerial lighting,fishing lights underwater,outdoor led flood lights...

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.